| This article is meant for the beginning stompbox builder who wants to learn how a solderless breadboard works and how to use it for prototyping. As a matter of

necessity, I'll also show some basic functions of using a multimeter for

continuity and voltage tests and introduce interpreting a schematic. From that

point, subsequent articles will cover setting up various effect circuits. |

| |

| Why A Breadboard? |

|

| So you have come up with a pinky-new circuit for the World's

Greatest Distortion/Trem/Delay, etc., etc. that will have guitar players

worldwide salivating to put one in their effects loop. You engineer everything

carefully, build with super high-quality components and fire it up. Of course, either:

|

|

|

| The solderless breadboard provides a way to set up a circuit for testing purposes without committing to a permanent build. It's the electronic equivalent of a kid's

Erector set; components can easily be added or removed, and whole sections can be reconfigured as many times as necessary to get to a finished design. |

|

|

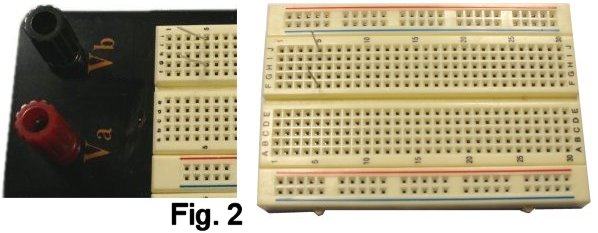

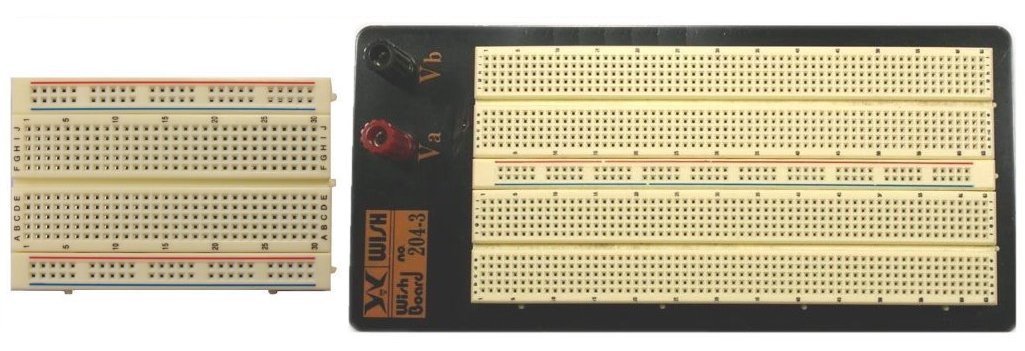

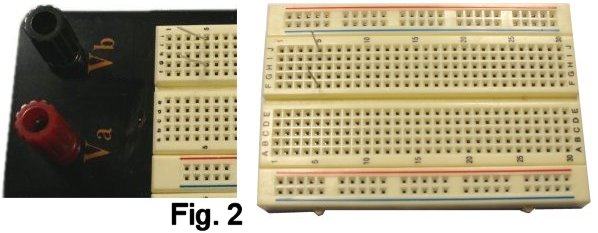

| The models that I use in this article: |

|

|

|

| are typical of many that are available from

mail-order shops. The plastic rails (often called "breadboard strips") are

made in several sizes, and they can usually be snapped together to create

larger arrays. For simple builds, a small strip like the one on the left is

usually fine. On the right is a typical product that has larger strips

attached to a metal base, convenient for bigger

layouts. More complex and expensive versions exist, some of which include built-in power supplies and mounting brackets for controls. My directions will mostly be applicable to anything you buy, whether from my Stock List or anywhere else. |

|

| How It Works - The "Bear Bones" |

|

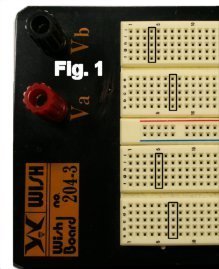

| Within each hole in the plastic rail is a spring-loaded contact that will

positively grip the lead of a component that you insert, but still allow you to

remove it easily. Each column of five holes is connected internally (Fig. 1). It

may help you get oriented by actually satisfying yourself that this is the case.

Insert short lengths of bare #22 or #24 wire into any two holes in a column (Fig.

2). |

|

|

|

| |

|

Now set the selector of your multimeter to the Continuity

position (or the lowest resistance scale if your instrument does not have a

Continuity position) and measure between the wires (Fig. 3).

|

| |

|

|

| OK so far? Many breadboards have |

| |

| Busses |

| |

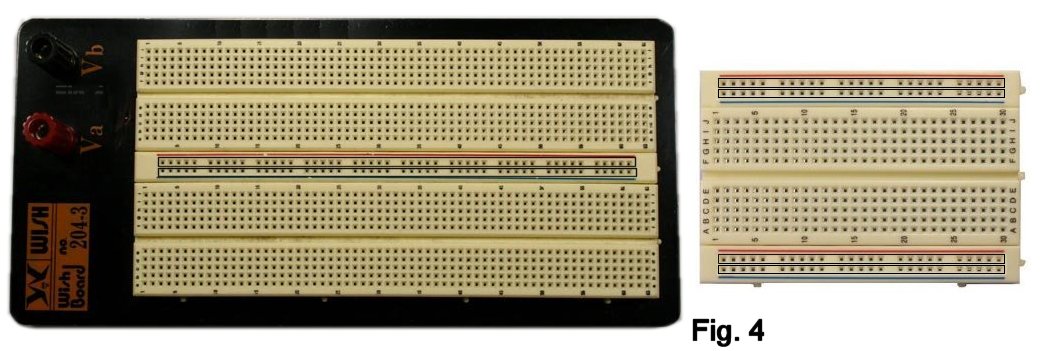

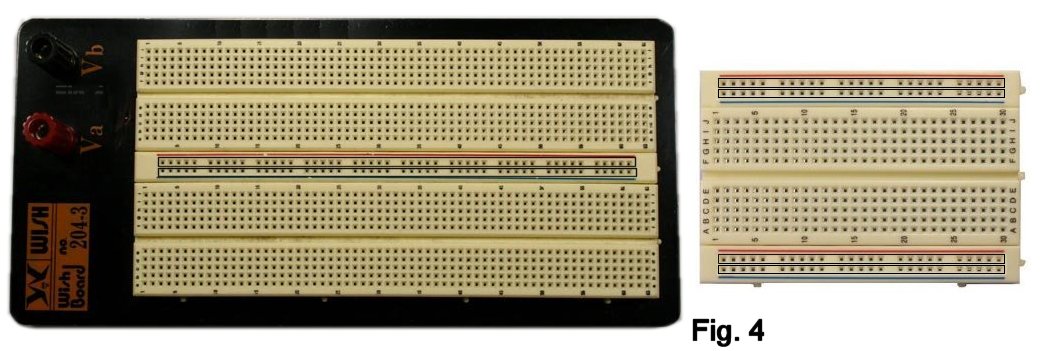

| A bus (in this case) is a row of holes connected horizontally

so that power can easily be distributed to the points in the circuit where it is

needed, and/or to provide a common ground. (I'll get more into that concept and

define it later.) The busses are outlined in figure 4: |

| |

|

|

Do the test with the multimeter if you need to to be sure that you

know what is--and is not--connected to what. While each bus in these breadboard

is connected all the way across, I have seen models in which the bus is split in

the middle; you have to connect the two halves

together if you want continuity across the full length.

You have probably noticed that the rows on each strip have

letters and the columns are numbered. This "indexing" is sometimes useful for

referring to specific locations, as we'll do later on.

|

|

|

Making Connections

|

|

|

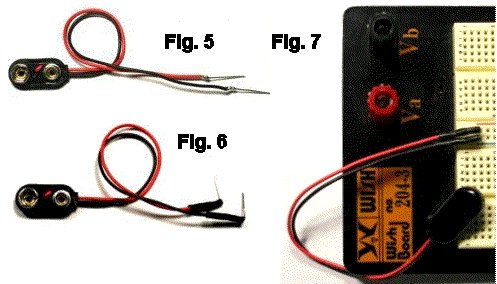

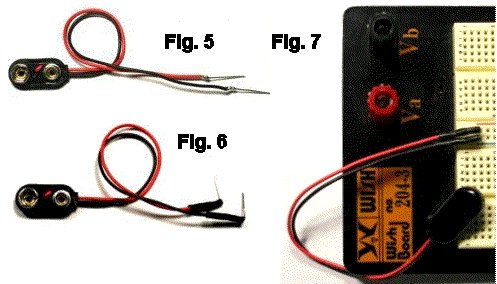

Let's begin by setting up a very simple circuit just to light an

LED. This will demonstrate a couple of necessary points before we tackle an

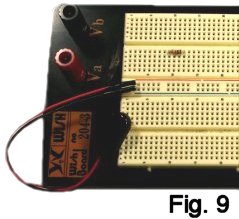

effect. This breadboard has red (+) and black (-) binding posts for connecting

power, but I usually use a 9-volt battery snap to which I have soldered a couple

of plug-in leads. It's very easy to make.

First, cut a couple of pieces of #22 or #20 bare wire about 1/2"

long. Wrap a few turns of the end of each battery lead around one of the pieces

and solder (Fig. 5.) (I will talk about where to find/buy connecting wire for

the breadboard in a minute.) Cover the solder joints with small pieces of 1/16"

heat shrink, and conform the tubing to the joint by rubbing it gently with the

barrel of your soldering iron Then put a right-angle bend in each end, and you

have a connector (Fig. 6.) It plugs conveniently into the busses of the

breadboard (Fig. 7.)

|

|

|

|

| Shown as a schematic, here is what we want to connect: |

|

|

|

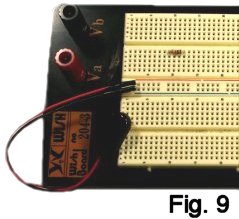

| Pretty simple, right? A schematic shows the logical connection

of components, but not necessarily the physical way that they are laid out. So

let's lay this out on the breadboard. First, cut off half the leads from a 10K

resistor (Brown, Black, Orange, Gold) and save the wire scraps for use later. Bend the

leads flush to the body, and plug the resistor into any two convenient columns

(Fig. 9); breadboarding is pragmatic and practical and does not have many fixed rules

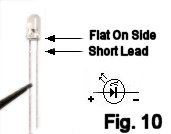

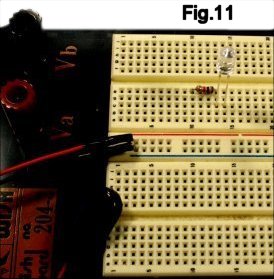

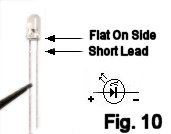

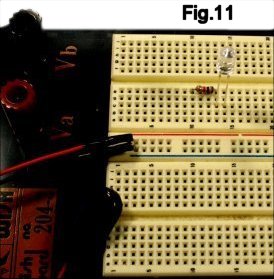

about what goes where. The LED is a diode by definition and so is polarized

(Fig. 10.) Plug it in with its positive lead in the same column as the

right-hand lead of the resistor (Fig. 11.) You have made the connection shown in

Fig. 12. Got the idea? |

|

|

|

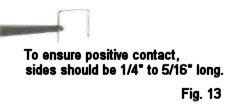

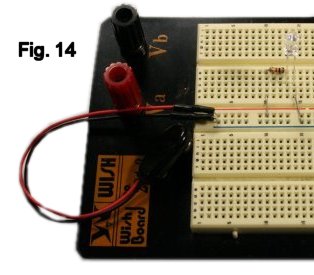

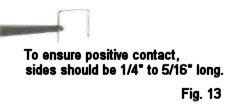

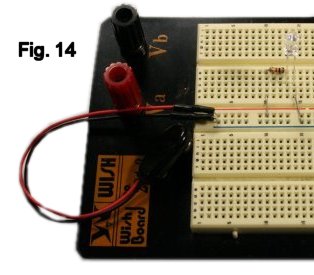

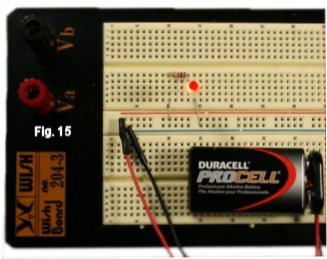

| Now finish the circuit. Create a couple of jumpers

from #22 or #24 bare stock (Fig. 13) and

plug these in to make the connections to the power supply busses (Fig. 14.)

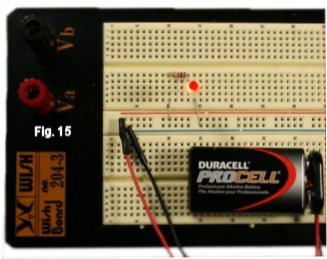

Connect the battery (Fig. 15) and let there be light! |

|

|

|

A few notes:

-

For purposes of illustration, I squared the corners of the

jumpers and made the hole-to-hole lengths exact, but neither is necessary for

routine work; as I noted earlier, breadboarding is pragmatic and based on speed

and convenience.

-

Jumpers can be made from insulated or bare wire. Use insulated

wire where there is any possibility that leads will short.

-

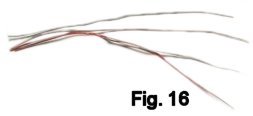

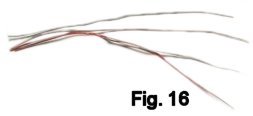

Wire for making jumpers can be bare or tinned copper, and most

breadboards will accommodate gauges from #20 to #24. You can find suitable

material in Wire and Cable on my Stock List or from other stores, but you can

also take advantage of free sources: Save the scraps of wire that result when you

trim component leads; many of these are perfect for jumpers that need to span

only two or three holes. Also, if you run across a job site where telephone

installation or removal is being done, look out for discarded pieces

of multi-pair cable that contain as many as 50 of these individual conductors

(Fig. 16):

Slice the outer jacket, remove a bunch of these wires, and you

will have all you need for many moons of experiments.

Are you ready to Rock and Roll? OK!!

At this point, you can proceed to the article on

Breadboarding A Silicon Fuzz

Face. I will add other effects to this series down the road. Welcome, and let

the Noise begin!

|